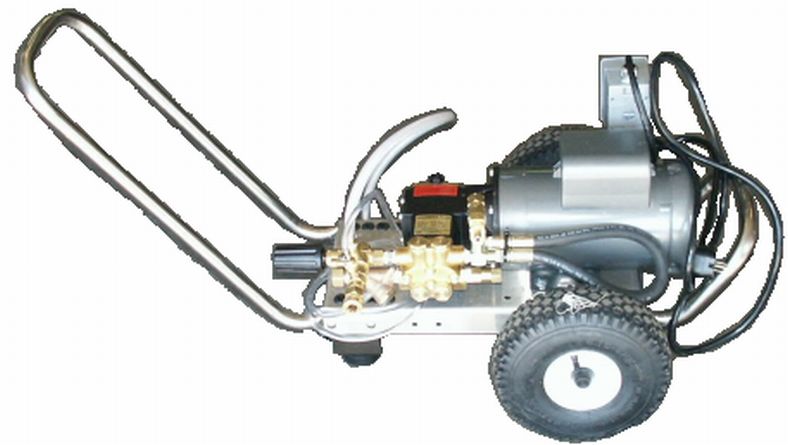

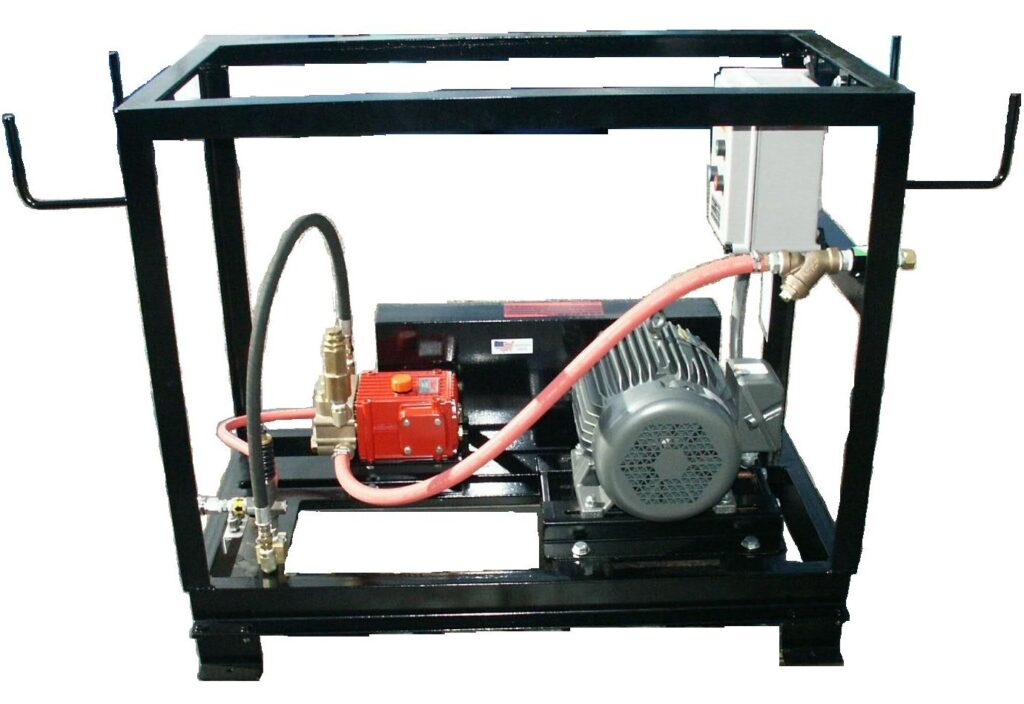

Electric Cold Water Pressure Washers

| Power Source | Motor |

| Heating Type | Electric |

| Temperature | Cold |

| Flow Rate | Up to 600 gpm |

| Pressure | Up to 10,000 psi |

| Drive | Up to 250 hp |

Pressure Washers, Sewer Jetters, Hydrostatic Test Equipment and Custom Pump Packages for Hazardous or Non-Hazardous areas

ACME provides solutions for industrial cleaning with powerful electric cold water power washers. The cold water pressure washers provide high pressure, flow-rates as well as drive. Additionally, because the water is cold, these power washers offer efficiency and economy for your heavy-duty cleaning requirements.

Hundreds of electric pressure and flow combinations available, flow rates to 600 gpm, pressures to 10,000 psi, drives to 250 hp for hazardous or non-hazardous areas.

Electric Cold Water Pressure Washer Specifications:

- Motor Starter: the standard enclosure for non-hazardous applications is NEMA 4X, for hazardous areas the standard is NEMA 7/4X.

- Electrical wiring: land-based application wiring is in compliance with the National Electrical Code and consists of PVC coated flexible steel conduit with liquid-tight connectors. Marine environment wiring is marine cable and glands with copper-free aluminum electrical fittings.

- Motor: TEFC (totally enclosed fan cooled) and in compliance with the Energy Independence and Security Act (“EISA”). Marine applications use a severe duty motor which meets the weatherproof requirements for IEEE 45 and USCG 259 marine duty (below deck).

- Drives: designs include v-belt drives, direct-coupled and c-face-mounted direct coupled.

- Pumps: options for various duty levels of operation.

Heavy Duty: Proven highest quality pressure washer pumps, operated at maximum rated rpm and up to maximum rated pressure.

Severe Duty: The same highest quality pumps operated at reduced rpm and pressure to extend the maintenance intervals and life of the pump.

Industrial Duty and Continuous Duty pumps are also available.

Standard Power Washer Features:

- Strainer: heavy-duty cast bronze.

- Thermal relief valve designed to prevent overheating of the pump.

- Unloader bypass valve, the primary pressure relief valve.

- Safety pressure relief valve is a redundant safety back up for the unloader valve.

- Chemical injectors are typically the downstream type where the chemical injector is located after the pump and in heated units, after the heater.

- Hoses sized for minimal pressure loss and a 4:1 safety.

- Spray gun assemblies typically consist of a trigger gun, lance, twin nozzle holder with high-pressure narrow fan nozzle and low-pressure chemical application nozzle.

- Frame heavy duty constructed of structural steel.

- Corrosion protection, the standard is two party high build epoxy and an option is a standard marine multi step coating. All nuts and bolts are 316 stainless steel.

Facebook

Facebook LinkedIn

LinkedIn Twitter

Twitter Instagram

Instagram YouTube

YouTube